Consisting of a winch at one end of a 30 meter table, a cable is drawn off along the table and attached to a skeleton chain track (it has no cross plates added). The table is then positioned by way of a hydraulic cylinder to create a ramp. The winch then pulls the chain up and onto the table.

The ‘loose” end of the chain is then attached and clamped to the large shaft. The shaft is then rotated using a hydraulic moor to “wind” up the completed track, which is then strapped up and lifted by crane and ready for transport to the customer.

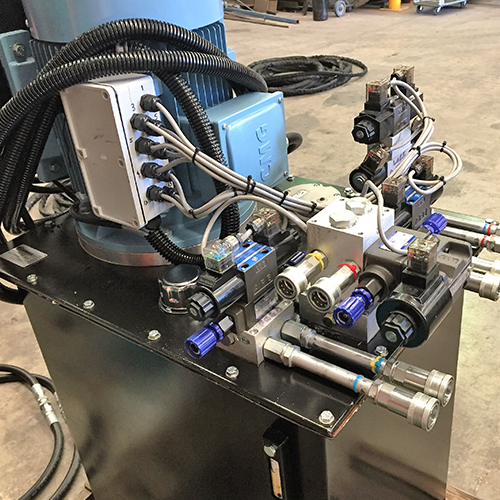

Hyspecs provided the hydraulic power pack, pipework and radio control. A new winch is in the works to replace the existing one which will provide a retard function so the winding up of the track can be better controlled.

Contact Hyspecs